The basic materials of currently used plastic films are mainly polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC) and polyester (PET). The surface properties of these materials vary greatly due to the polarity of their functional groups, degree of crystallinity and chemical stability. These factors significantly impact the adhesion strength of printing ink layers.

For example, PP, PE, and PET have non-polar surface structures, what makes them chemically stable. They are not easily penetrated or dissolved by most ink solvents, resulting in poor bonding strength. Therefore, these materials must undergo surface treatment prior to further processing. This treatment aims to activate the plastic surface layer, generating new chemical bonds and creating a rougher surface, which enhances the bond and adhesion strength between the ink and the plastic surface.

Plastic films often undergo corona treatment in production lines such as casting, blow molding, and BOPP. Antioxidants and slip agents are commonly added to the plastic films as additives, which are time-effective. The best results from corona treatment are achieved when printing is done immediately after the treatment.

The technical process of corona treatment is a crucial step in the production of plastic films to improve their surface properties, particularly to enhance adhesion for printing, coating, or lamination.

- Preparation: The plastic film is unwound from a roll and fed into the corona treatment station.

- Discharge Application: High-voltage, high-frequency electrical discharge is applied to the film through electrodes. This is the actual "corona" part of the process.

- Surface Modification: The electrical discharge generates a corona, a plasma field created by ionizing the air gap between the electrodes and the film surface. This corona effectively bombards the film with high-energy electrons.

- Chemical Change: The bombardment of electrons breaks the molecular bonds on the surface of the film, creating new polar functional groups and increasing the surface energy of the film.

- Adhesion Improvement: The newly formed polar groups on the film surface can form stronger chemical and mechanical bonds with inks, adhesives, or other coatings, leading to improved adhesion.

- Control and Optimization: The effectiveness of corona treatment is controlled by several parameters, including the power output of the generator, the speed of the film as it passes through the electrodes, the distance between the electrodes and the film, and the material properties of the film itself.

- Post-Treatment: After corona treatment, the film is immediately ready for subsequent operations such as printing. The treatment's effects are time-sensitive, with the best results achieved when printing is done shortly after treatment.

- Output Power: The intensity of the electrical discharge is crucial for effective treatment.

- Electrode-Film Distance: The gap between the electrodes and the film surface must be optimized for uniform treatment.

- Film Material: Different materials respond differently to corona treatment, requiring adjustments to the process parameters.

- Film Speed: The speed at which the film moves through the treatment area affects the exposure time to the corona.

-

- Corona Generator

Corona treatment is a surface electric discharge process that enhances the adhesion of plastic or metallized films. Most plastic films (such as polyolefin films) are non-polar polymers with low surface tension. Corona treatment is used to increase the surface energy of these films, as known inks and adhesives cannot adhere firmly to their surfaces in normal conditions.

-

- Corona Treatment Station

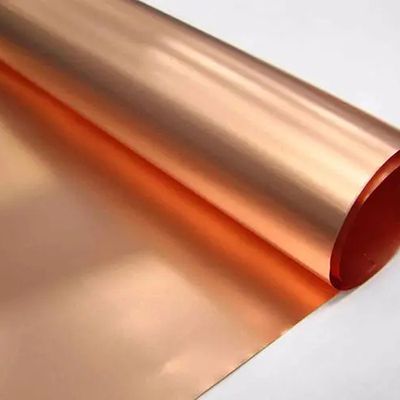

Corona treatment station, also known as discharge station or discharge treater, is a crucial component of the corona treatment system, commonly used in the corona treatment for materials such as plastic films, metal foils, sheets, and paper. Sanxin offers various types of corona treatment stations for customers to choose from, including double-sided, single-sided, side-open, full-closed, semi-closed, and full-open discharge treaters.