-

Plastic Film Corona Treatment System

Plastic Film Corona Treatment System-

By subjecting the plastic film to corona treatment, the film’s surface energy can be significantly increased, enhancing the wetting and adhesion of liquids/inks on the material. This results in better printing and composite quality of film.

Read More

-

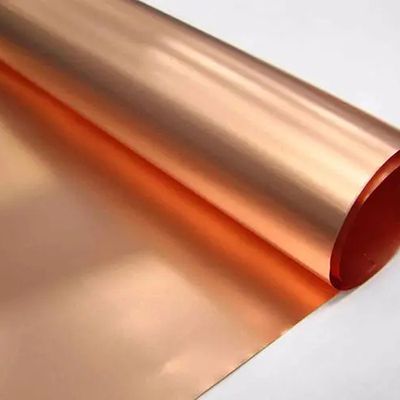

Metal Foil Corona Treatment System

Metal Foil Corona Treatment System-

By subjecting the metal foil to corona treatment, the film will have better wetting tension, higher surface dyne value, and greater adhesion. This results in better printing, higher composite strength, or adhesive durability during subsequent production processes. It is recommended to use ceramic electrodes for metal foil corona treatment.

Read More

-

Lithium-ion Battery Aluminum Foil Corona Treatment System

Lithium-ion Battery Aluminum Foil Corona Treatment System-

By subjecting the aluminum foil of batteries to corona treatment, the foil surface can be evenly and finely coated with nanometer-sized conductive graphite and carbon-coated particles. This conductive material allows for excellent static conductivity, collecting microcurrent from active substances. As a result, the contact resistance between positive/negative electrode materials and current collectors can be hugely reduced.

Read More

After corona treatment, the adhesion between the substrate and the coating is improved, reducing the need for adhesive usage. This breakthrough technology leads to a remarkable enhancement in the overall performance of batteries.

-

Cable Corona Treatment System

Cable Corona Treatment System-

Corona treatment can be used on different cable materials like PTFE, nylon, PE, TPE, XLPE, PEEK, etc. Corona treated cables may no longer suffer problems such as poor adhesion of inkjet printing and lettering transfer.

Read More

-

Woven Sack Corona Treatment System

Woven Sack Corona Treatment System-

Corona treatment on woven sacks can effectively remove oil stains, increase surface tension, enhance lamination strength, improve stacking height, and extend storage time.

Read More

-

Paper Corona Treatment System

Paper Corona Treatment System-

Corona treatment on paper can significantly improve its surface wetting, creating an active surface with enhanced surface tension. It also helps to remove oil and dust from the paper’s surface.

Read More

-

Plastic Sheet Corona Treatment System

Plastic Sheet Corona Treatment System-

Plastic sheets are produced in a plastic extruder or plastic calendar machine that heats and melts the raw material (particles).

Read More

Corona treatment is applied to increase surface tension, which enhances the ink adhesion during printing. The method of corona treatment may vary depending on the thickness of the sheets.

-

Jacket Pipe Corona Treatment System

Jacket Pipe Corona Treatment System-

Corona treatment effectively enhances the adhesion between High-Density Polyethylene (HDPE) jacket pipes and polyurethane foam plastic. It works by introducing polar groups and roughening the inner surface of HDPE pipes, along with the “pipe-in-pipe” closed foaming process. These factors significantly increase the bonding strength between HDPE jackets and polyurethane foam, resulting in improved overall quality of insulation pipes.

Read More

Corona Generator

A complete corona treatment system consists of three parts: corona generator, discharge station, and transformer.

-

- Corona Generator The CW1000 series corona generator utilizes a resonant switch, along with reliable integrated circuits and power devices. It efficiently converts grid electricity into high-frequency, high-voltage AC using a bridge inverter circuit comprising power tubes.

-

- Corona Treatment Station Corona treatment station, also known as discharge station or discharge treater, is a crucial component of the corona treatment system, commonly used in the corona treatment for materials such as plastic films, metal foils, sheets, and paper.

Want to find out more or not sure where to start?

Our technicians are always here to help you.

Contact Us