Corona treatment of metal foils is an advanced technique designed to enhance the surface characteristics of foils through the ionization of gases. This process involves the creation of an electric arc discharge, powered by a high-voltage AC source, which effectively ionizes atmospheric gases such as oxygen and nitrogen. The resulting physicochemical reactions induce a transformation in the foil's surface chemistry and microstructure. By increasing the surface energy, the treatment significantly improves the foil's wettability and adhesive qualities. The ultimate objective of this sophisticated treatment is to elevate the overall performance of the foil material's surface, making it more suitable for its intended applications.

Corona treatment stands out as a pivotal surface enhancement technology, markedly boosting the surface attributes of foil materials. This treatment is particularly beneficial for sectors like food packaging, medical devices, and electronic components, offering further improvements:

- Elevated Surface Properties of Foil

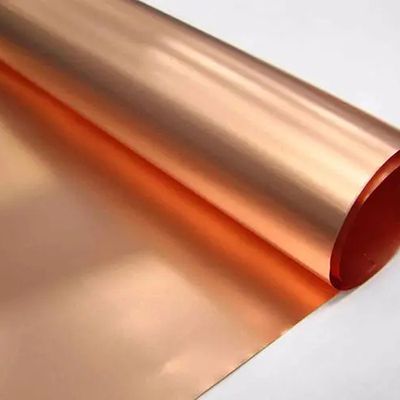

Through corona treatment, the surface energy of the foil is augmented, which bolsters its wettability and adhesion capabilities. The foil becomes more amenable to printing, coating, and bonding with diverse materials, achieving better packaging performance. - Improved Sealability and Preservation of Freshness

The enhanced surface energy of the foil material amplifies the adhesion with other substances. This enhancement is crucial for aluminum and copper foil products used in packaging, leading to better sealability and extended freshness of the contents. - Prevention of Static Charge and Corrosion

Static charge accumulation on metal foil surfaces during production can affect processing, packaging and lamination. Corona treatment effectively mitigates static buildup, safeguarding against potential packaging disruptions. Moreover, it plays a significant role in reducing oxidation and corrosion, thereby prolonging the functional lifespan of the foil material.

-

- Corona GeneratorCorona treatment is a surface electric discharge process that enhances the adhesion of plastic or metallized films. Most plastic films (such as polyolefin films) are non-polar polymers with low surface tension. Corona treatment is used to increase the surface energy of these films, as known inks and adhesives cannot adhere firmly to their surfaces in normal conditions.

-

- Corona Treatment StationCorona treatment station, also known as discharge station or discharge treater, is a crucial component of the corona treatment system, commonly used in the corona treatment for materials such as plastic films, metal foils, sheets, and paper. Sanxin offers various types of corona treatment stations for customers to choose from, including double-sided, single-sided, side-open, full-closed, semi-closed, and full-open discharge treaters.