Prior to the release of wire, cable, and optical cable products, marking process is employed to imprint essential identifiers like production batch numbers, lot information, specifications, and manufacturing dates onto the product surface. This step is essential for traceability and quality control. The standard materials used for these cables are rubber, PVC, PE, PTFE (Teflon), and nylon. Their inherent low surface adhesion properties often lead to the premature wear of these markings. They are easily scratched or marred, with the markings susceptible to being completely removed with just a minor scrape from a fingernail.

Some cable manufacturers have made various attempts, such as switching to inks with higher adhesion properties or using thermal pressing methods to imprint labels. However, these methods are temporary solutions that do not address the root cause, resulting in low efficiency, poor quality, and potential environmental pollution problems.

The corona treatment machine works as surface pre-treatment equipment for various silicone rubbers, plastics, and other materials. The corona treatment machine can enhance the surface adhesion and hydrophilicity of the materials. The principle behind the corona machine's treatment of inkjet code printing fall-off is that the bombardment of the material surface with plasma will break down the surface molecules, allowing them to combine with the atoms in the plasma to form new chemical structures. These new structures are able to adhere to the inkjet printing, making it less likely to fall off.

When materials such as rubber, PVC, PE, which constitute the outer layers of cables, undergo plasma bombardment, a significant transformation in their surface properties occurs. This advanced treatment alters their inherent non-adhesive nature, converting them into substrates with enhanced ink receptivity. This change addresses the core issue of ink markings that flake off with ease, providing a durable and reliable solution for clear, long-lasting identification on cables.

-

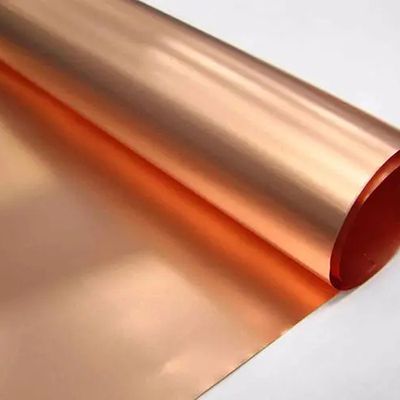

- Corona GeneratorCorona treatment is a surface electric discharge process that enhances the adhesion of plastic or metallized films. Most plastic films (such as polyolefin films) are non-polar polymers with low surface tension. Corona treatment is used to increase the surface energy of these films, as known inks and adhesives cannot adhere firmly to their surfaces in normal conditions.

-

- Corona Treatment StationCorona treatment station, also known as discharge station or discharge treater, is a crucial component of the corona treatment system, commonly used in the corona treatment for materials such as plastic films, metal foils, sheets, and paper. Sanxin offers various types of corona treatment stations for customers to choose from, including double-sided, single-sided, side-open, full-closed, semi-closed, and full-open discharge treaters.